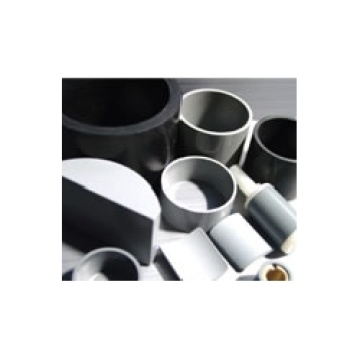

Round Plastic Bonded NdFeB Magnet

Product Description

General Information

Collectively known as Rare Earth Magnets, Neodymium Iron Boron (NdFeB)

and Samarium Cobalt (SmCo) magnets are alloys of the Lanthanide group of

elements. Rare Earth magnets are the most advanced commercialized

permanent magnet materials today.

The Bonded NdFeB Magnets material can be produced with close tolerances

off tool, with little or no finishing required. The energy product of

the bonded form is much lower than that of the sintered form - up to 10

MGOe. The bonded NdFeB is isotropic and can be magnetized in any

direction, and with multiple poles.

Manufacturing Methods

Compression - this is a technique whereby a special form of NdFeB

powder is blended with a plastic carrier material, die pressed and then

heated. Parts made in this way can be of complex shapes and come off the

tool with close tolerances, requiring no further finish machining.

Injection - NdFeB powder is blended with a plastic material and

injection molded. The resulting parts have energy products in the 5 MGOe

range, but can be made with extremely intricate shapes.

Assemblies

We are able to manufacture metal and other components of finished sub assemblies using our CNC machining facilities.

Assemblies can be fabricated by adhering magnets with adhesives to suit

a range of environments, by mechanically fastening magnets, or by a

combination of these methods. Due to the relatively brittle nature of

these magnet materials, press fits are not recommended.

When multiple magnets are assembled in repelling positions, it is

advisable to use mechanical fastening in addition to adhesives, since if

adhesives were to give way, repelling magnets may dislodge and endanger

personnel using them. Our design engineering team will be happy to

assist you in designing housings for your magnet assemblies.

Surface Treatments

Epoxy coating is mostly common used for bonded NdFeB Magnets.

Machining

Bonded NdFeB is easily machined. Coolants must be used while machining

this material in order to avoid spontaneous combustion of powder.

Machining this material removes a layer of protective coating, and

re-coating for corrosion resistance may be necessary.

Magnetizing and Handling

Isotropic bonded NdFeB materials can be magnetized in any direction, or

with multiple poles. Special magnetizing fixtures are required in order

to achieve multiple pole magnetization. Such multiple pole fixtures may

cost several thousand dollars depending on complexity of design and

production rate requirements.

Temperature Effects

Magnetic properties of NdFeB deteriorate rapidly above about 130

Centigrade, depending on the grade of material, and the permeance

coefficient of the magnet in operation. The higher the permeance

coefficient the magnet operates at, the higher the temperature it will

withstand. High Hci NdFeB materials operating at a high permeance

coefficient can operate to about 210 Centigrade. Shapes, Sizes, and

Grades Available Isotropic bonded NdFeB can be specially formulated to

meet special requirements, with energy products from 1 to 10MGOe, as

required.

Magnetic Properties of plastic Bonded NdFeB:

| Grade | Remanence Br | Normal Coercivity Hcb | Intrinsic Coercivity Hcj | Max. Energy Product (BH)max | MaxOperating | Density |

| KGs | KOe | KOe | MGOe | ℃ | g/cm3 | |

| NEOBM-4 | 3.5-4.5 | 3.0-3.5 | 8-10 | 3.5-5.0 | 150 | 4.5-5.0 |

| NEOBM-6 | 5.0-6.0 | 4.0-4.5 | 8-10 | 5.0-7.0 | 150 | 5.8-5.8 |

| NEOBM-8 | 6.0-6.7 | 4.5-5.5 | 8-10 | 8.0-9.0 | 140 | 5.8-6.0 |

| NEOBM-8H | 5.6-6.5 | 5.0-5.8 | 13-17 | 7.5-9.0 | 120 | 5.6-6.0 |

| NEOBM-10 | 6.8-7.0 | 5.0-5.5 | 8-10 | 9.0-10.0 | 120 | 6.0-6.2 |

| NEOBM-12 | 7.0-8.0 | 5.2-6.0 | 8-11 | 10.0-12.0 | 130 | 6.2-6.6 |

| NEOBM-12D | 7.0-8.0 | 5.5-6.0 | 9-12 | 10.0-12.0 | 140 | 6.2-6.6 |

Physical Properties of plastic Bonded NdFeB:

| Average Reversible Temperature Coefficient | 0.09-0.1%/C |

| Coefficient of Thermal Expansion[25-200℃] | 4.8X10-6/℃ |

| Compressive Strength | 96Kg/cm |

| Curie Temperature Tc | 400℃ |

| Electrical Resistivity | 14000μΩ-cm |

| Hardness | 35-38HRB(NEOBM8/10/12) |

| Required Magnetizing Force [open Circuit] | >25KOe |

Coating of Plastic Bonded NdFeB:

| Surface Coating | Color | Quality | |

| Epoxy Coating | black | grey | good |

| Parylene Coating | Transparent | excellent | |

Dimension range of Plastic Bonded NdFeB:

| | Length mm (Outer Diameter) | Width mm (Inner Diameter) | Thickness mm | |||

| Min. | Max. | Min. | Max. | Min. | Max. | |

| Block | 5.0 | 100 | 5.0 | 100 | 0.8 | 50 |

| Ring | 5 | 100 | 3 | 95 | 0.8 | 50 |

Contact us if you need more details on Bonded NdFeB Magnet. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Bonded NdFeB、Round Bonded NdFeB Magnet. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Permanent Magnets > Bonded NdFeB Magnets

Premium Related Products